Causes of damage to die -casting production molds

Release time:

2022-05-07

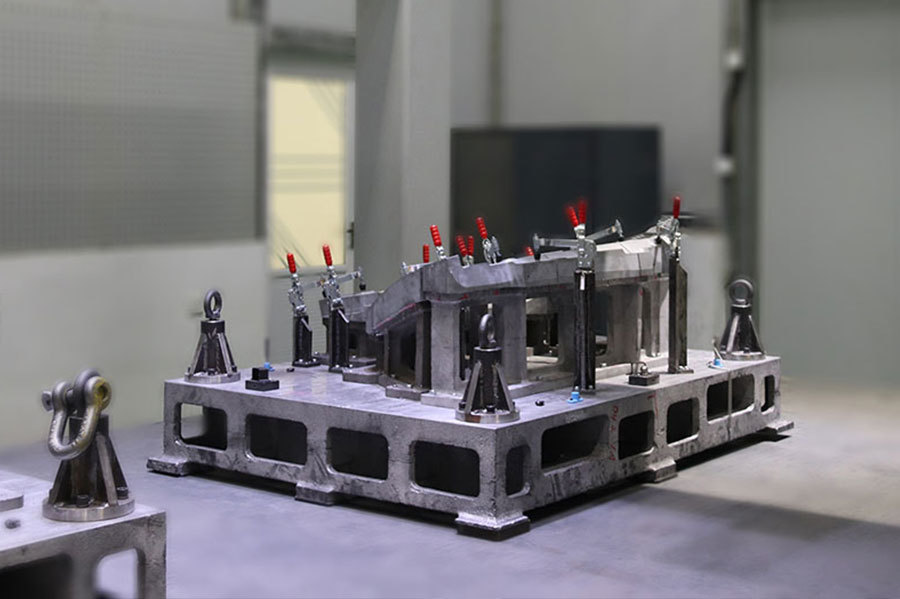

In die -casting production, the most common form of car mold damage is cracks and cracking. Stress is the main cause of damage to mold. Heat, mechanical, chemistry

In die -casting production, the most common form of car mold damage is cracks and cracking. Stress is the main cause of damage to mold. Heat, mechanical, chemistry, and operational impact are all sources of stress, including mechanical stress and thermal stress, and stress produces:

1. In the process of mold processing and manufacturing

1. Quality problem of rough forging. Some molds only produce cracks after a few hundred pieces, and the cracks develop quickly. It may only be guaranteed during forging, and the branches of the branches, mixed carbides, shrinking holes, bubbles and other loose defects in the steel are extended and streamlined. The final quenching deformation, cracking, crispy cracking during use, and the tendency of failure have a great impact.

2. The cutting stress generated during the final processing of the car, milling, and shaving, this stress can be eliminated by annealing in the middle.

3. During the grinding of quenching steel, the grinding stress is generated, and friction heat is generated during grinding, which produces a softened layer and decarburized layer. After the H13 steel is grinded, it can be heated to 510-570 ° C, and the stress annealing is eliminated for one hour of the thickness of the thickness.

4. Electric spark processing is stress. The white bright layer of a layer of enriched electrode elements and electronically aggressive elements is generated on the surface of the mold, which is hard and crispy. This layer will have cracks and stress. When processing the electric spark, the high frequency should be used to minimize the white bright layer. The polishing method must be removed, and the ignition treatment must be carried out.

2. During the mold processing process

Improper heat treatment will cause the mold to crack and make an early newspaper, especially the use of quality adjustment, no quenching, and then the surface nitride technology. After the die casting thousands of molds, the surface cracks and cracks will appear. During steel quenching, stress is the result of the thermal stress during the cooling process and the tissue stress superposition during the phase change. The quenching stress is the cause of deformation and cracking. The solid must be ignited to eliminate stress.

3. During the production process of die casting

The mold should be preheated to a certain temperature before production. Otherwise, it will cause cold when the high -temperature metal liquid is charged, causing the temperature gradient of the inner and outer layer of the inner and outer mold to increase the thermal stress, causing the surface of the mold to crack and even crack. During the production process, the mold temperature continues to rise. When the mold temperature is overheated, it is easy to produce sticky molds, and the motion components fail to cause the surface damage of the mold. The cooling temperature control system should be set to keep the mold work temperature within a certain range.