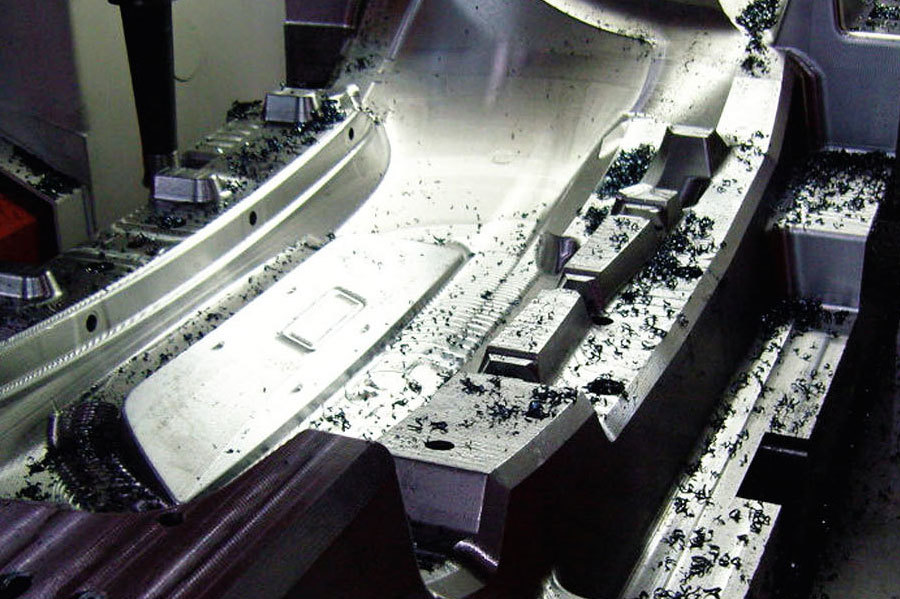

Auto bumper mold design

Release time:

2022-05-07

However, as consumers are now getting higher and higher in appearance, the internal division of only high -end car bumpers has gradually replaced the first structure.

Plastic bumper replacement metal insurance is the development trend of automotive molds. The design of plastic bumper molds currently mainly adopt two structures.

1. outer shape

2. Internal division

The first structure is relatively simple and the second structure is relatively compared to the mold structure, mold strength, etc., which are much more complicated than the first type.

However, as consumers are now getting higher and higher in appearance, the internal division of only high -end car bumpers has gradually replaced the first structure. As the company's confidentiality, I probably talk about the internal division:

Because the dividing line is set on the B side, if the conventional oblique surface is launched, the launch mechanism will be interfered when the mold is opened with the oblique block at the fixed mold hook, causing the mold damage. Therefore, avoid the collision between the diagonal top and the fixed model becomes a design point.

Generally, the following points are solved

1. When the mold is opened, the oblique top block is launched simultaneously, that is, when the mold is opened, the push plate (also uses nitrogen springs) is used to maintain the relative position of the push board and the fixed mold.

2. Use the deformation of the product to pull the end of the parts inward through the horizontal slider inside the diagonal block, and use the guide rail control itineraries at the end of the horizontal slider to leave the end of the part at the end of the fixed mold.

3. Open the mold to separate the product from the fixed mold.

4. Continue to push out and control the horizontal sliding movement outward through the guide rail at the end of the horizontal slider to make the product deform and reset

5. Finally continue to top up, so that the products are removed