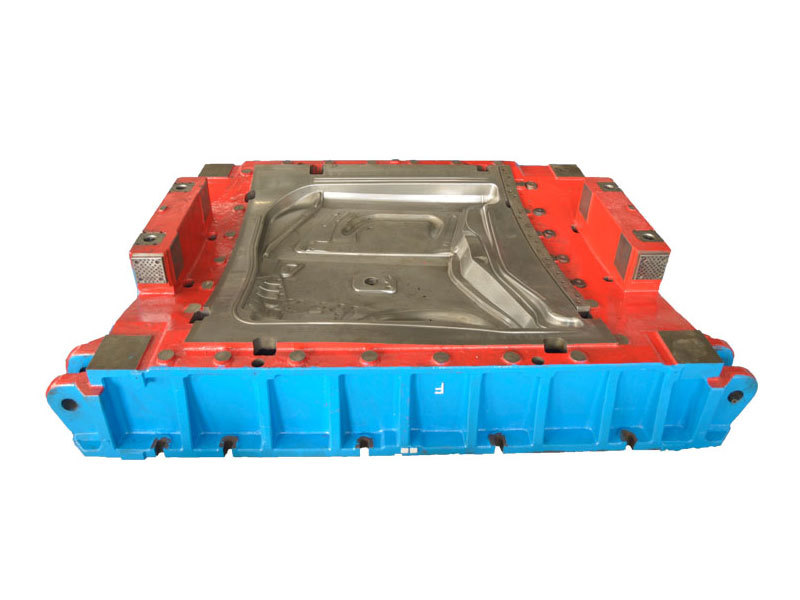

Side circumference mould

This picture shows that our company designed and manufactured the overall side of the sedan sideways.

Keywords:

Category:

Description

This picture shows that our company designed and manufactured the overall side of the sedan sideways. The overall side circumference of the car is the top priority of the cover part of the car, because it is the largest of the cold -mode stamping part of the vehicle; Many components have the most matching relationship; it requires smooth surfaces, clear ridgeline, and peripheral size and accuracy cannot be greater than 0.7mm; the safety and noise of the car must directly determine the plastic deformation of the stretch It has sufficient strength; the beautiful requirements of the car on the surface of the outer board on the surface of the car are not scratched at all, and the tactile inspection has no convex bags and dark pits; it can be seen that the quality of the overall side circumference directly affects the quality and appearance of the car , And the side circumference plate pull -up model is crucial to ensure the overall side of the side circumference. Whether the success of the stretch process determines whether the stamping process is reasonable and whether the part can be pushed out.

The product characteristics of the overall sideways require the structure to ensure that the plate material during the stretching process except the outer feeding of the plate, and the plates in the two different shapes of the plate of the plate are material. This forming process cannot be achieved through the structure of single or dual -motion pull -up models, and only through the structure of the three -motion stretch. The complex shape of the product and the depth of pulling the depth requires that the mold not only does the outer board and the plates in the two different entrances, but the pressure of the pressure in the two doors can be adjusted to cope with complex changes. To this end , The overall sideways decide to use the outer coil plate pressure through the top pole of the machine tool. The plates in the two different shapes of the door are achieved through two independent inflatable nitrogen cylinder pipeline connection systems, and the pressure can be adjusted. The pressure is adjustable. And ensure that the observation pressure is random and convenient, and the adjustment pressure is simple and convenient.

Due to the reasonable process and mold structure design, the well -known casting factory has been preferably a well -known casting plant, which makes the mold manufacturing and debugging process smooth. All processing can meet the equipment capabilities of our factory. And received praise from customers.

Related Products

Product Inquiry

Our staff will contact you within 24 hours (working day). If other services need, please call the service hotline: +86-317-8185763