ABOUT US

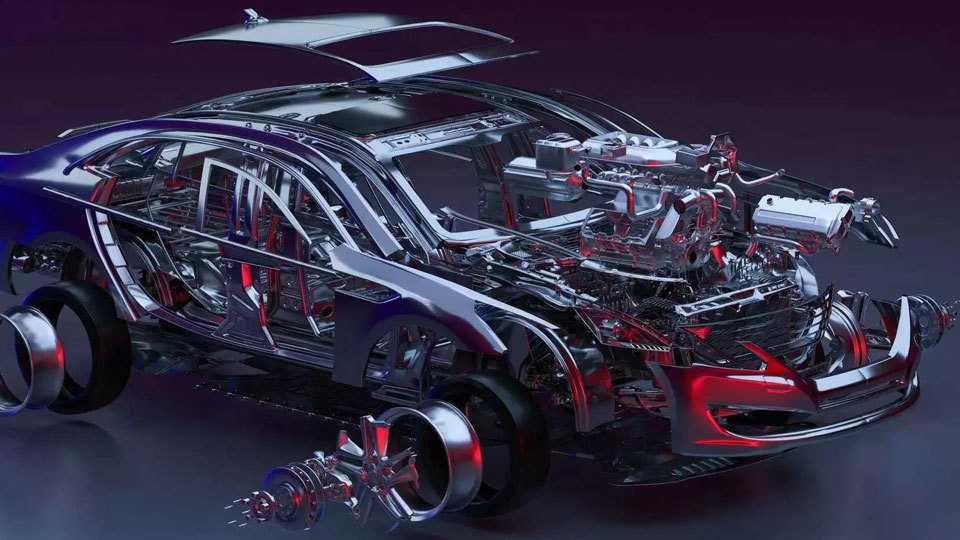

The design, manufacturing, stamping, and processing of the cold -built -in mold, inspection, and welding fixture in the car body are integrated

Production experience

CNC and hydraulic equipment

Company employee

Annual output

HUANGHE DIE & MOULD

Provide Perfect Car Coverage Mold Solutions

Cangzhou Huanghe Die & Mould Co., Ltd. established on November 20, 1997. It is a modern company that integrates the design, manufacturing, stamping, and processing of cold molds, inspection, and welding fixtures in the car body. There are more than 600 sets of automotive coverage mold molds, which can provide users with model scanning, inspection, welding fixture, and vehicle numerical models to establish a full range of services until work design and development. The company is located in the Fuzhuang Industrial Park, one kilometer south of Botou City, Hebei Province, China. The total area covers an area of 40,000 square meters and a total construction area of 18,000 square meters. There are more than 20 high and intermediate engineers.

VIEW MORE +PRODUCTS

There are more than 600 sets of annual production of car coverage molding molds, which can provide users with model scanning, inspection, welded fixture, and vehicle numerical models.

Technical Strength

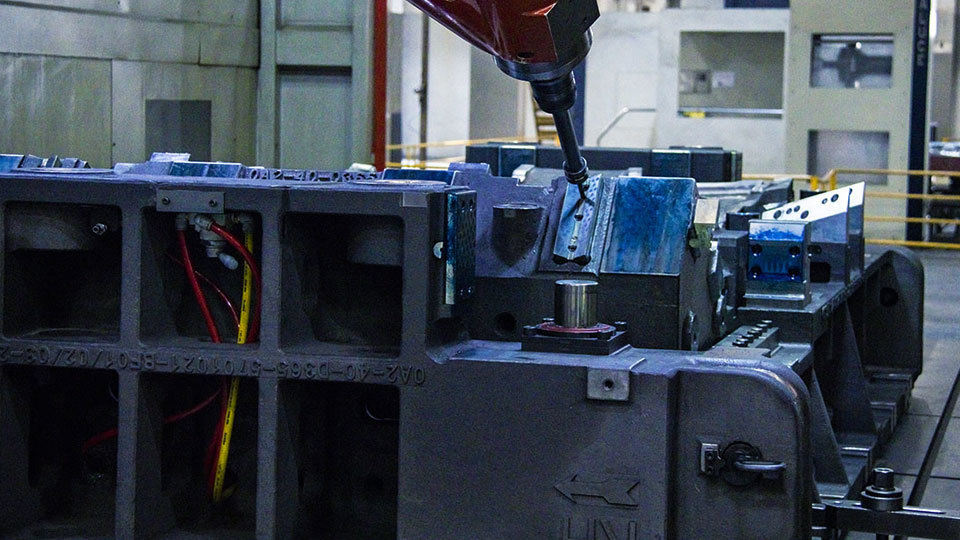

The company reproduces huge sums of money to make technical transformation, purchases 14 large imported three-axis CNC processing centers, 2 large imported Longmen five-sided high-speed processing centers, 7 small CNC machining centers, 2 three-coordinate measurement machines, large stamping debugging equipment YB27- 2 1600T hydraulic press, 1 YQK27-1250T hydraulic press, 2 YB27-800T hydraulic press, Y32-500T hydraulic press 3

NEWS CENTER

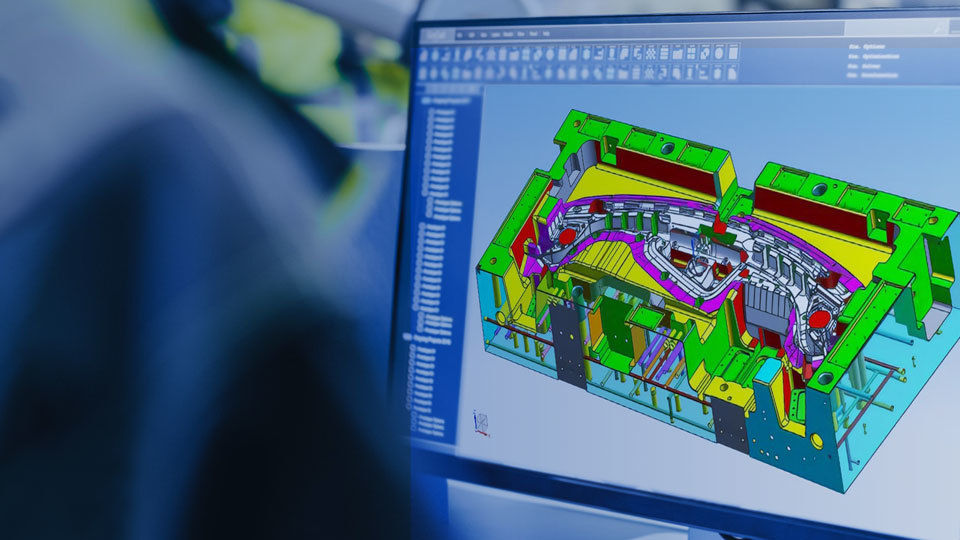

The company has a high -quality professional team, and mold development has achieved CAD/CAE/CAM integration

2022/05/07